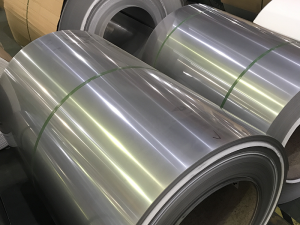

410S igwe anaghị agba nchara

Nkọwa

Nkọwapụta:

1.Standard: ASTM A240, JIS G4304, EN10088

2. Ọkwa: 200usoro&300usoro&400usoro

3. Ọkpụrụkpụ: 0.03mm - 6.0mm

4. Obosara: 8mm-600mm

5. Ogologo: dị ka arịrịọ ndị ahịa

6. Elu: 2D,2B, BA, Mirror okokụre, N04, Hair Line, Matt finish, 6K, 8K

7.Technology: oyi adọta / oyi na-ekpo ọkụ / ọkụ na-ekpo ọkụ

Akụrụngwa:

| Ụdị | Ọkwa | Ọkwa | Akụkụ kemịkalụ% | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Ndị ọzọ | |||

| Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50 - 7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316 Ti | 1,4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1 cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0,035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1 cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Ozi bụ isi

Igwe anaghị agba nchara 410s, yana ezigbo nguzogide corrosion na machinability, ọ bụ ebumnuche zuru oke nchara na ịkpụ ngwá ọrụ ígwè.410S bụ ụdị ígwè nke nwere ike imeziwanye nkwụsị nke corrosion na nhazi nke 410 steel.410S bụ ígwè dị elu nke nwere ike imeziwanye ihe mgbochi corrosion nke 410 ígwè.A na-eji ya maka agụba turbine na akụkụ okpomọkụ dị elu.

• Nkọwapụta: AISI 410s, ASTM 410s

• Emechara: Ba elu, 2b elu, No.1 (akpụkpọ anụ ọcha), 2D elu, No.4 (frosted), HL (esere waya), 8K elu nwere ezigbo mma elu.

• Mill tolerances on ọkpụrụkpụ & flatness metụtara.Kpọọ JM Steel ma ọ bụrụ na ị chọrọ kpọmkwem nha ma ọ bụ ọka ntụziaka.

410S Teknụzụ igwe eji eme ihe

1D - Elu nwere udi granular na-akwụsị, nke a makwaara dị ka elu igwe.

Nkà na ụzụ na-ahazi: ịgbagharị ọkụ na-ekpo ọkụ + na-egbutu ogbunigwe peening pickling + oyi na-atụgharị + ịhịa aka n'ahụ.

2D - Acha ọcha dị ntakịrị.

Nkà na ụzụ na-ahazi: ịgbagharị ọkụ na-ekpo ọkụ + na-egbutu ogbunigwe peening pickling + oyi na-atụgharị + ịhịa aka n'ahụ.

2B - Silver na-acha ọcha nke nwere ncha mma na ịdị larịị karịa elu 2D.

Teknụzụ na-ahazi: ịgbagharị ọkụ na-ekpo ọkụ + na-egbutu ogbugba peening pickling + oyi na-atụ mpịakọta + ịhịa aka n'ahụ + ịhịa aka n'ahụ na mkpụgharị iwe.

Ba - Ngosipụta elu dị mma, ngosipụta dị elu, dị ka elu enyo.

Teknụzụ na-ahazi: ịgbagharị ọkụ na-ekpo ọkụ + na-agbapụ ogbunigwe peening pickling + oyi na-agbagharị agbagharị + ịhịa aka n’ahụ + ihicha elu elu + imenyụ na mkpụgharị iwe.

No.3 -- Ezigbo gloss, oke ọka n'elu.

Nhazi teknụzụ: polishing na tempering rolling maka 2D ma ọ bụ 2B na 100 ~ 120 abrasive ihe (JIS R6002).

No.4 - Ezi gloss, mma ahịrị n'elu.

Usoro nhazi: polishing na tempering rolling maka 2D ma ọ bụ 2B na 150 ~ 180 abrasive ihe (JIS R6002).

HL --isi awọ isi awọ nwere ogologo ntutu.

Nkà na ụzụ nhazi: ngwaahịa 2D ma ọ bụ ngwaahịa 2B nke nwere granularity kwesịrị ekwesị nke ihe abrasive maka ịchacha elu bụ ọka abrasive na-aga n'ihu.

MIRRO -- Pụrụ Iche.

Teknụzụ nhazi: ngwaahịa 2D ma ọ bụ ngwaahịa 2B nwere oke nha kwesịrị ekwesị nke igwe ihe na-egweri na polishing na mmetụta mirror.